AAC PANELS FOR WALLS AND FLOORS

2 in 1: AAC Sheathing and Cladding Panels for wood or steel framing. AAC, ideal for stucco finish.

Steel-reinforced AAC subfloor panel designed to fit structural supports spaced at 16″ and 24″ O.C.

Specially crafted 2″-3″ AAC firewall panel engineered for fire resistance, durability, and reliable building performance.

AAC Sheathing & Cladding

The best for exterior walls

AAC, an excellent substrate for stucco finish

Replacing stucco with AAC panels

Cost-effective and time-efficient. Any finish can be applied: stucco, plaster, veneer, thin brick, brick, stone, or siding.

AAC panels replace 3-coat stucco

AAC: The Stucco Solution, panels that resist sagging, warping, or cracking, keeping joints invisible and finishes long-lasting.

No OSB or PLYWOOD needed

Non-combustible and water resistant, providing strength and moisture control for reliable performance and durability.

R-Value 2.4 AAC insulation

R-Value 2.4 AAC insulation improves thermal performance, helping reduce energy use and leading to up to 40% savings.

AAC SHEATHING & CLADDING

Faster Installation

- Prefabricated AAC panels

- Fast installation (700 ft² per day by a 2–3 person crew).

Higher Quality

- More insulative, leading to huge energy savings.

- Stronger, durable & hassle free (does not crack unlike 3-coat stucco).

- Fire and water resistance (no mold unlike EIFS).

Lower Cost

- Saving up to 40% less than other systems.

- AAC installs in a fraction of the time vs other systems.

AAC Firewall

Designed for fire resistance

Faster installation during framing

Faster installation during framing with no need for specialized labor, making AAC panels efficient and cost-effective.

Firewalls with Acoustic Advantage

2–3 hr fire rating and 58 STC acoustic performance, replacing shaftliner in firewalls, party and demising walls.

AAC FIREWALL

Faster Installation

- Prefabricated AAC panels.

- 50% faster install compared to Shaftliner.

- Extremely simple system/assembly, less components.

Higher Quality

- Higher insulation, leading to huge energy savings.

- Durable, stronger, and designed to be hassle free.

- Excellent sound insulation with a 58 STC rating.

Lower Cost

- 20% - 30% less than the Shaftliner System.

- No extra materials needed, cutting total project cost.

- Lightweight design cuts transport expenses.

AAC Subfloor

A 2 in 1 Subfloor Solution

For 16"/24" O.C. joists and trusses

Install finish directly over subfloor with no self-leveling concrete or extra backer layers required, saving time and labor.

No OSB or PLYWOOD needed

Non-combustible and water resistant, eliminating the need for OSB or plywood while providing long-lasting durability.

AAC SUBFLOOR

Faster Installation

- Directly nailed or fastened over joists and trusses.

- No joint sanding unlike plywood subfloor.

- Fast, clean, and simple installation process.

Higher Quality

- No squeaking, ensures quiet and stable floors

- Non-combustible.

- Highly acoustic.

- Water resistant.

- Termite proof.

Lower Cost

- Saving up to 30% in costs compared to alternative building methods.

- AAC installs in a fraction of the time, eliminating 3 steps vs other systems.

We are the future of exterior and demising walls, floors, and roofs.

Want to know more? Subscribe to a newsletter.

AAC Benefits to the Builder & General Contractor

High-quality construction in less time and at a lower cost.

Robust Concrete

AAC is a highly durable building material, providing long-lasting qualities to your buildings.

Structural

AAC can be used in a wide variety of construction projects, including residential and commercial buildings, as well as industrial and infrastructure projects.

Light Weight

AAC blocks are lightweight which makes it easy to handle, install and transport.

Lower Cost

AAC is a cost-effective building material that can save builders money on both; the materials and labor costs of construction.

Eco-Friendly

AAC is a non-toxic, non-combustible material that does not emit harmful chemicals or pollutants, contributing to LEED points for your project.

Labor Savings

Easier & Faster Installation. AAC cuts and sands with conventional tools.

Stronger and Longer Lasting

AAC is a durable building material that is resistant to fire, pests, and extreme weather conditions, ensuring long-lasting structures.

Water Resistant/No Mold

AAC is resistant to mold and mildew.

Comfort

AAC has a high thermal mass which helps to regulate indoor temperature, making the home more comfortable.

Acoustic Insulation

AAC has great acoustic insulation properties, this helps to reduce sound transmission between rooms and between the home and the outside.

Insurance Savings

AAC is a non-combustible building material, which means it does not burn or emit toxic fumes when exposed to fire. This can lead to lower insurance rates.

Energy Savings

AAC has high thermal mass and insulating properties, allowing for improved energy efficiency in buildings, resulting in lower energy bills.

AAC Special Features

Autoclaved Aerated Concrete

AAC is a lightweight and eco-friendly type of concrete, widely recognized as cellular or aerated concrete.

AAC panels and blocks

AAC products include prefabricated panels and blocks offered in different sizes and applications.

Made with cutting-edge tech

Made from natural materials like cement, lime, silica sand, and a small amount of powdered aluminum.

Autoclave cured for strength

Cured under 12 bars of pressure at 375°F for 13 hours, ensuring density, durability, and long-term stability.

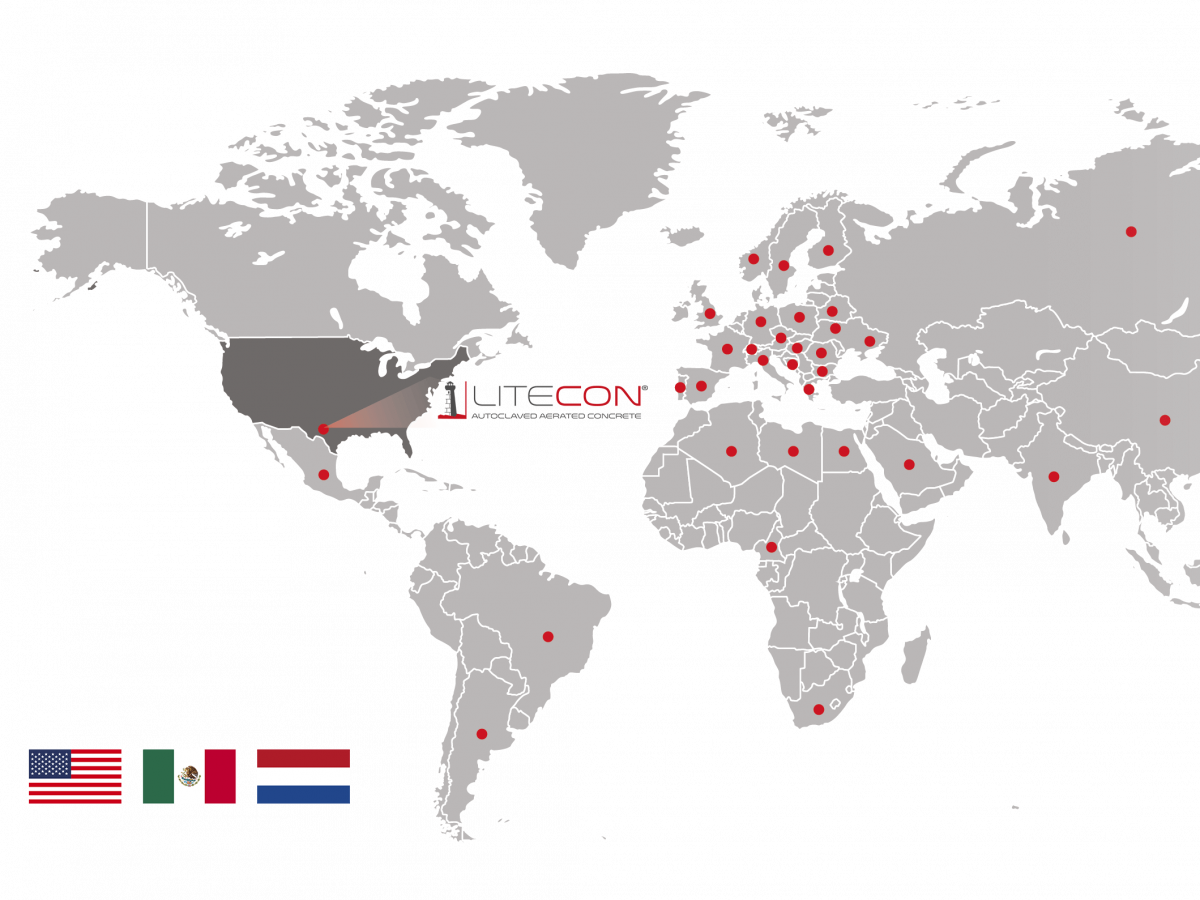

Partners

Litecon is partnered with Aircrete Mexico and Aircrete Europe, a global leader in AAC with more than 50 years of experience, known as the most advanced developer, manufacturer and producer of AAC technology. The company has built over 100 different plants in 20 countries on 6 different continents.

AAC is the future

AAC Litecon panels are the future of panels for walls, floors, roofs and façades for residential, commercial and industrial buildings.AAC Panels for Walls & Floors.

OUR FACTORY

Products

Manufactured at the largest AAC plant in North America, producing 32 million ft² annually.

Manufacturing

Our manufacturing process complies with ASTM standards for quality and reliability.

Production

We ship AAC panels and blocks across North America and into Central America.